Receipt Monitoring

Many power plants receive fuel from outside vendors. Power plants use the data to check incoming quality against contracts. This data can be used to get discounts for suppliers, weed out outliers in quality, or supplier evaluations. Recently SABIA, Inc. has installed applications in which the SABIA analyzer is used to evaluate coal quality truck by truck on both incoming and load out facilities. This data is used to accept, reject or route individual coal trucks.

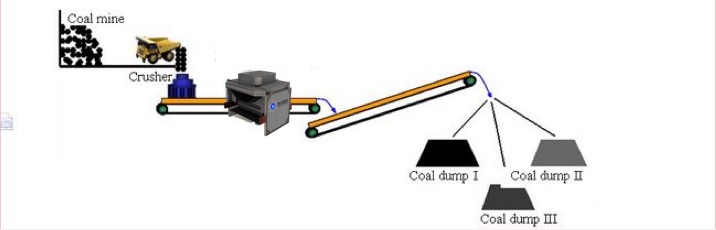

Sorting

Another application for SABIA analyzers is for sorting. In this application the customer uses data supplied by the analyzer to sort fuel into piles of various grades. The user can thus avoid the use of low heat or potentially damaging fuels. They can then stockpile them separately for return to the supplier or blend them in with higher grade coals later.

SABIA analyzer data can be used either by humans to control transport of stacking equipment or SABIA software can be used to control flop gates, stacker/reclaimers, and other hardware to automatically sort based on various quality criteria decided by the user.

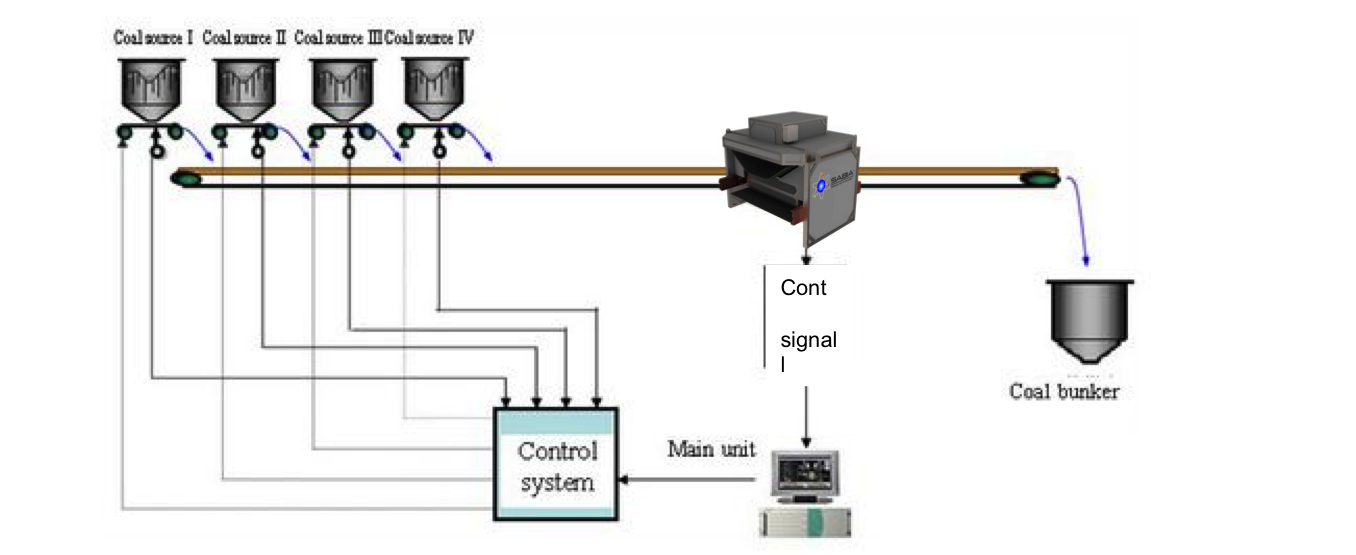

Another way SABIA analyzers are used in the fuel yard is for coal mixing. In this case fuels of various grades are added to a single pile or silo such that the total of the pile or silo achieves an average grade that is desired by the customer. The act of reclaiming the pile or silo is done in a way that causes the different grades to be combined, thus mixing the coal.

SABIA software and analytical tools allow the user to track the contents of the pile or silo from multiple sources and to assign an average value for the pile or silo. SABIA control software can be used to control flop gates and feeders to both control the input and the output of the pile or silo.

The word “mix” rather than “blend” is used because the method does not necessarily provide a homogeneous result, but can be a cost effective solution for combining multiple grades of fuel. This method allows for significant savings in fuel costs, additive reduction, reduced derate risk, and improved boiler life.

The most sophisticated and also expensive method of managing a fuel yard with a SABIA analyzer is a blending operation. In this case the user may employ a number of the previously mentioned methods to gather data and prepare sources of fuel to blend.

SABIA analyzers and fuel management software and control systems can provide a custom solution to improve fuel quality.