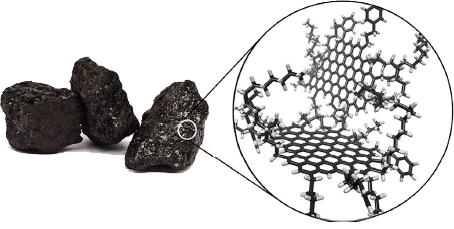

1: THE BEGINNING: GM-1000 Chute Analyzer (Coal) ~ Pyramid Mine, 1986

The 1st commercial PGNA Analyzer installation in the world. SABIA founder Clint Lingren was a founder of Gamma Metrics and at the time was leading their R&D department.

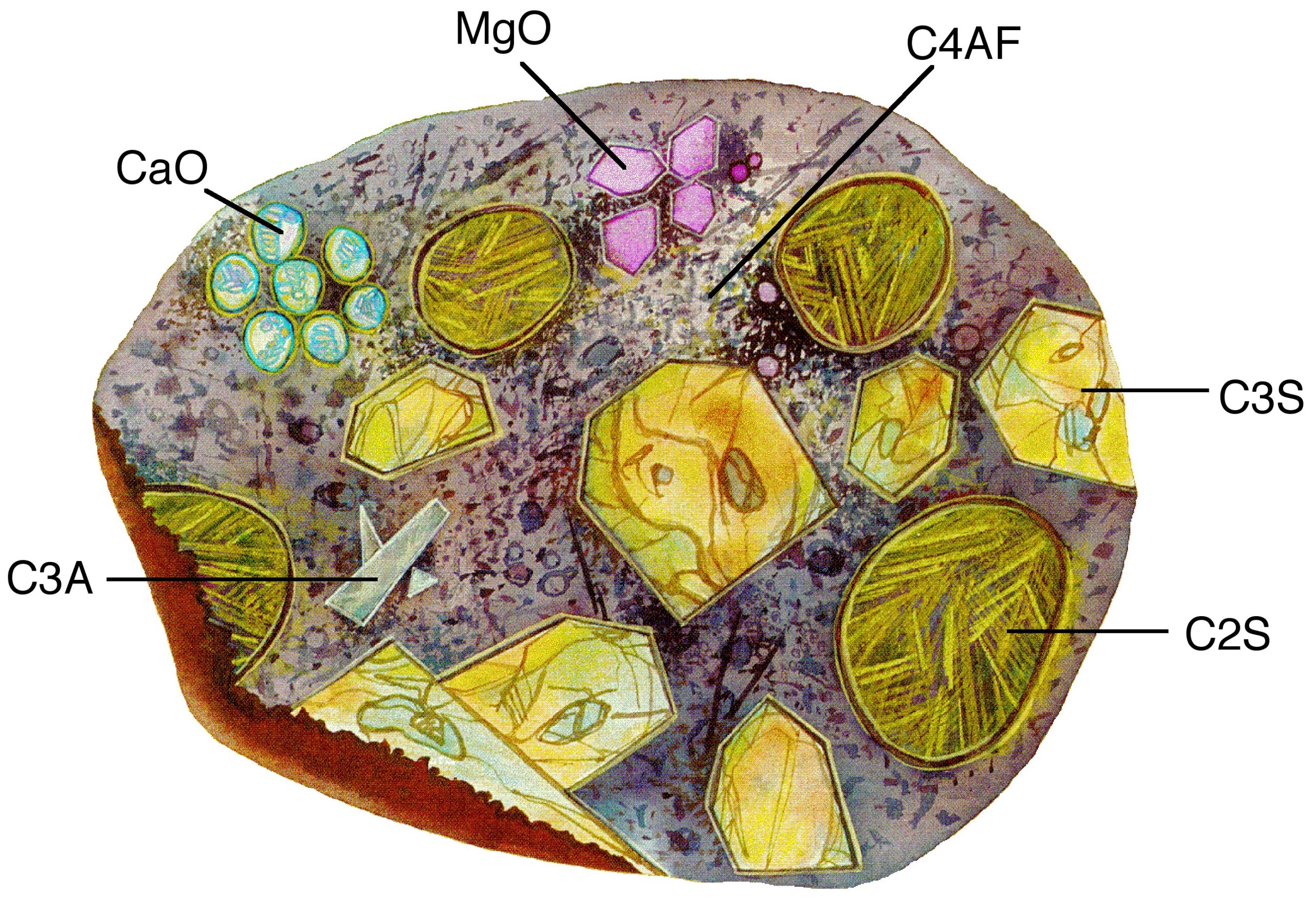

2: NEW APPLICATIONS: GM-1000 Chute Analyzer (Cement) ~ Phoenix Cement, 1987

The first analyzer for a material other than coal. Installed by Gamma-Metrics with the direction and participation of SABIA founders. This analyzer opened the door for new materials and applications including copper, iron ore, phosphates, and other minerals. New applications are still emerging today.

3: CROSS BELT: GM Cross-Belt Analyzer (Cement) ~ Phoenix Cement, 1994

The first analyzer installed around a conveyor belt. While much smaller than the GM-1000, it was still large and the weight required a dedicated support structure. This reduced the cost of equipment and installation.

4: SABIA INNOVATION: XC-5000 On-Belt Analyzer (Coal) ~ 20 Mile Mine, 2002

This analyzer was small and light enough to mount on the conveyor stringers. It was installed 3000 ft underground. Developed and installed by SABIA, this analyzer significantly reduced the costs of PGNA Analyzer equipment and installation.

This analyzer also included the 1st web browser enabled software allowing operators to access analysis results from any web enabled device on the site network. Web Browser based software still remains the basis for all SABIA software today.

5: RETROFITS: 1812HC Chute Analyzer Retrofit (Cement) ~ Lafarge Alpena, 2005

These two analyzers were initially installed by Thermo Gamma Metrics in the early 1990s. They began having substantial problems every few weeks, so the original electronics were replaced with new SABIA electronics. These analyzers are still in use today and SABIA has retrofitted a variety of other outdated analyzer models at other sites.

6: TOTAL MOISTURE: All SABIA On-Belt Analyzers (Coal) ~ Worldwide, 2005

SABIA introduced PGNAA enabled moisture measurement. This eliminated the need for SABIA analyzers to have a microwave moisture meter. PGNAA total moisture measurement provided greater accuracy and reduced equipment costs.

7: SIZE & PERFORMANCE: X1 On-Belt Analyzer (Coal) ~ Eagle Butte, 2009

The 1st of SABIA’s X1 Series analyzers. The Model X1 provided an even smaller and lighter frame. This further reduced analyzer costs and improved performance.

8: CONTINUOUS SLURRY: X1-XP On-Pipe Analyzer (Phosphate) ~ Simplot Vernal, 2014

The SABIA X1-XP slurry analyzer is mounted directly around the slurry pipe and is the first and only analyzer capable of a continuous analysis for 100% of the material flowing through the process.Prior slurry analyzers relied on multiplexers to recirculate slip streams from slurry lines. They required constant maintenance had only analyzed a small periodic sample of the material being processed. The SABIA X1-XP is revolutionizing slurry processes by providing complete data that was never before available.

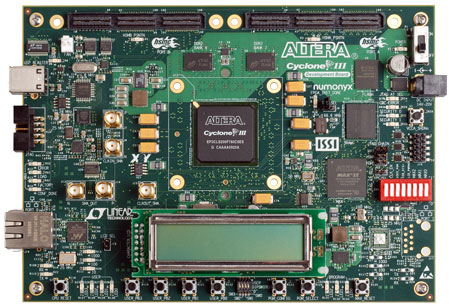

9: NEW ELECTRONICS & AUTOMATION: X1-LiNX On-Belt Analyzer (Cement) ~ CEMEX Lyons, 2014

This analyzer installation boasts FPGA technology, integrated electronics, high performance detectors, and fully network enabled communication. It eliminated the need for an external control cabinet with extensive cabling. It also simplified installation and improved performance.

This installation also marks the release of RHEA, the most user friendly Raw Mix Control Software to date. RHEA offers custom dashboards to multiple users for fully automated feeder control. While other sophisticated control software had been developed in the past, this release of RHEA drastically reduced the complexity and cost to implement raw mix automation.

10: DIRECT CV MEASUREMENT: X1 Series On-Belt Analyzers (Coal) ~ Alcoa 3 Oaks Mine, 2015

The 1st analyzer to directly measure the Heating Value or Gross Calorific Value (GCV: BTU/lb, kcal/kg) of coal. Previously, the GCV was calculated but SABIA development of the measurement technique provides improved accuracy over larger variations of coal.

Stay tuned for what comes next, SABIA is continuously innovating the PGNA Analyzer World!

Click the LinkedIn icon above to share this post with any colleagues who would be interested in learning more about the origins of SABIA technology. Contact us if you would like any additional information about these installations or the history of PGNAA.